Sustainability in the Skandia Gateway project

The Port of Gothenburg is the only port in Scandinavia that offers direct services between Europe and the Far East – a route that is served by the world’s largest container vessels. Following completion of the Skandia Gateway project, the fairway and the harbour basin will be 16,5-17.5 metres deep. This investment is strategically important for Swedish industry, as it assures future imports and exports using direct services.

Significant environmental and societal gains

Vessels that are deeper and broader can make direct calls from other continents and arrive with more freight per vessel, offering significant environmental and economic gains. Higher freight volumes per vessel improve transport efficiency, generating economies of scale.

The Port of Gothenburg is the largest and most prominent freight hub in Scandinavia, offering a nationwide catchment area in which a sustainable rail network is prioritised for freight transport. Climate impact can be reduced significantly if freight is transported over long distances using an electrified rail system instead of by road.

Environment

Planned measures, including deepening and broadening of the fairway and quay reinforcement, require an environmental permit under the Environmental Code. An application for an environmental permit was submitted to the Land and Environment Court in autumn 2020. A number of inquiries and investigations has been conducted, and an environmental impact assessment will be prepared.

Consultation

The preparation of an environmental impact assessment is a process, and a key part of this process is consultation. Consultation involves providing information about planned measures and obtaining data from public authorities, associations, organisations, and the general public that would form part of the assessment. Consultation took place during spring and summer 2020. Read more about the consultation process here.

The environmental impact assessment includes an investigation of the effects of turbidity, noise, vibrations, and air emissions. Experience gained from dredging, blasting, and piling is invaluable when assessing the impact and consequences of planned measures. This is demonstrated by the experience gained from the projects that were run in 2002-2004. Back then similar measures were implemented in the fairway, harbour basin, and the eastern part of the Skandia Harbour. With the requisite management and monitoring, the projects could be completed without any lasting negative impact on the environment. Permission was granted on 29 September 2020. Permission for quay measures was given on 29 September 2022 to the Port of Gothenburg and for dredging on 6 March 2023 to the Maritime Administration.

Financing

The joint project Skandiaporten is estimated to cost SEK 2.8 billion based on 2017 price levels, with approximately SEK 1.255 billion allocated to quay measures by the Port of Gothenburg and around SEK 1.6 billion earmarked for fairway measures by the Swedish Maritime Administration. This sum includes:

Deepening and widening of the fairway to accommodate vessels with a maximum draft of up to 16.5 meters, along with adjustments to fairway markings.

Deepening and widening of the harbor basin adjacent to the western quay.

Deepening of the western quay and reinforcement of the quay structure.

The Swedish Maritime Administration and the Port of Gothenburg are jointly evaluating the possibility of further deepening, up to a maximum of 17.5 meters. The cost of this extension is not included in the forecast for the base project. If a second quay is also to be deepened, this would require a separate decision by the Port of Gothenburg and its owner.

Securing access to the world.

ABOUT THE PROJECT

ABOUT US

TIMELINE

PRESS & MEDIA

UPDATES

SUSTAINABILITY

CONTACT

EN

/

SV

The Port of Gothenburg is the only port in Sweden that can receive the world’s largest vessels. At present they are unable to do so fully loaded. To address this problem and ensure Swedish industry is able to meet the demands of the future, extensive deepening of the fairway is required. The project, known as Skandia Gateway, is being run jointly by the Swedish Maritime Administration and the Port of Gothenburg.

©SKANDIA GATEWAY 2020

29 September 2025

Ongoing climate efforts

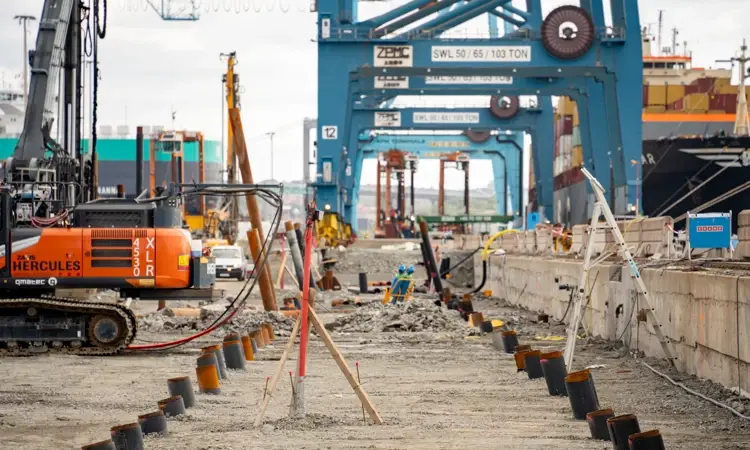

The Skandia Gateway fairway project demonstrates that sustainability and large-scale infrastructure can go hand in hand. By choosing smarter materials, applying innovative methods, and working closely with contractors, The Port of Gothenburg has significantly reduced the climate impact of the quay construction, while keeping costs under control. The outcome is clear proof that climate-smart construction is not only possible but also profitable.

10,000 tons less CO₂ in quay construction – so far

Large-scale construction does not have to mean a heavy climate footprint. In the Skandia Gateway project, The Port of Gothenburg, together with NCC, has shown that sustainable material choices and new approaches in the quay construction phase can make a substantial difference – without driving up costs.

So far, emissions have been cut by 30% compared to traditional construction methods. The additional cost of climate measures accounts for just 1% of the total project budget – tangible evidence that sustainable construction can be both effective and cost-efficient.

“Measured against the benefits, the costs are small compared with the significant climate gains we achieve. Together with NCC, we have scrutinized every detail of construction, procurement, and methodology. By carrying out climate calculations that highlight the impact of different choices, daring to challenge conventional methods, thinking creatively, and consistently focusing on cutting emissions, we refined our initial targets and have now achieved a 30% reduction. Along the way, we’ve also gained a deeper understanding of how construction affects our CO₂ footprint, knowledge that will allow us to set even tougher requirements in future projects,” says Jan Andersson, Project Manager for Skandia Gateway at The Port of Gothenburg.

A collaborative achievement

The ability to cut emissions during quay construction rests on strong teamwork between project management and those carrying out the work on site.

“It is a great achievement to have reduced CO₂ emissions in this project so successfully. But no matter how much we plan and calculate, nothing would be possible without the skill and dedication of the people placing piles, concrete, and sheet piling on site,” says Jan Andersson.

How the emissions were reduced

Materials & construction

Material choices with lower climate impact, recycled steel instead of new, saved 15% of the entire project’s climate impact

Optimization and minimization of constructions, for example reduction of concrete thickness

Smaller proportion of cement – concrete with slag as a binder

Optimized use of concrete – the steel pipe piles are partially filled with crushed material

Thinner layers of coarse concrete

More efficient sheet piling, smaller dimensions and extent

Proposals and solutions from both officials and skilled workers on site

Machinery & transports

100% HVO100 in all machinery and transports

Electrically powered machines for piling and drilling

Consolidated orders and planned castings with other stakeholders provide fewer transports

Larger load capacity in excavation trucks provides fewer trips

Charging stations for electric cars on the construction site

Return loads – bringing new material back from the landfill

No unnecessary idling

Circular construction

Sorting & reuse of asphalt, steel, and rock masses between projects

Holes in the sheet piling = less future operation & maintenance

Reuse of masses & materials: steel piles, steel beams, asphalt, cutting waste

Pulled-up sheet piling reused for seals

Innovative work mothodology

Ongoing climate calculations showing decreasing emissions over time

Efficient procurement work with CO2 as a selection criterion

Sustainability in the Skandia Gateway project

The Port of Gothenburg is the only port in Scandinavia that offers direct services between Europe and the Far East – a route that is served by the world’s largest container vessels. Following completion of the Skandia Gateway project, the fairway and the harbour basin will be 16,5-17.5 metres deep. This investment is strategically important for Swedish industry, as it assures future imports and exports using direct services.

Significant environmental and societal gains

Vessels that are deeper and broader can make direct calls from other continents and arrive with more freight per vessel, offering significant environmental and economic gains. Higher freight volumes per vessel improve transport efficiency, generating economies of scale.

The Port of Gothenburg is the largest and most prominent freight hub in Scandinavia, offering a nationwide catchment area in which a sustainable rail network is prioritised for freight transport. Climate impact can be reduced significantly if freight is transported over long distances using an electrified rail system instead of by road.

Environment

Planned measures, including deepening and broadening of the fairway and quay reinforcement, require an environmental permit under the Environmental Code. An application for an environmental permit was submitted to the Land and Environment Court in autumn 2020. A number of inquiries and investigations has been conducted, and an environmental impact assessment will be prepared.

Consultation

The preparation of an environmental impact assessment is a process, and a key part of this process is consultation. Consultation involves providing information about planned measures and obtaining data from public authorities, associations, organisations, and the general public that would form part of the assessment. Consultation took place during spring and summer 2020. Read more about the consultation process here.

The environmental impact assessment includes an investigation of the effects of turbidity, noise, vibrations, and air emissions. Experience gained from dredging, blasting, and piling is invaluable when assessing the impact and consequences of planned measures. This is demonstrated by the experience gained from the projects that were run in 2002-2004. Back then similar measures were implemented in the fairway, harbour basin, and the eastern part of the Skandia Harbour. With the requisite management and monitoring, the projects could be completed without any lasting negative impact on the environment. Permission was granted on 29 September 2020. Permission for quay measures was given on 29 September 2022 to the Port of Gothenburg and for dredging on 6 March 2023 to the Maritime Administration.

Financing

The joint project Skandiaporten is estimated to cost SEK 2.8 billion based on 2017 price levels, with approximately SEK 1.255 billion allocated to quay measures by the Port of Gothenburg and around SEK 1.6 billion earmarked for fairway measures by the Swedish Maritime Administration. This sum includes:

Deepening and widening of the fairway to accommodate vessels with a maximum draft of up to 16.5 meters, along with adjustments to fairway markings.

Deepening and widening of the harbor basin adjacent to the western quay.

Deepening of the western quay and reinforcement of the quay structure.

The Swedish Maritime Administration and the Port of Gothenburg are jointly evaluating the possibility of further deepening, up to a maximum of 17.5 meters. The cost of this extension is not included in the forecast for the base project. If a second quay is also to be deepened, this would require a separate decision by the Port of Gothenburg and its owner.

29 September 2025

Ongoing climate efforts

The Skandia Gateway fairway project demonstrates that sustainability and large-scale infrastructure can go hand in hand. By choosing smarter materials, applying innovative methods, and working closely with contractors, The Port of Gothenburg has significantly reduced the climate impact of the quay construction, while keeping costs under control. The outcome is clear proof that climate-smart construction is not only possible but also profitable.

10,000 tons less CO₂ in quay construction – so far

Large-scale construction does not have to mean a heavy climate footprint. In the Skandia Gateway project, The Port of Gothenburg, together with NCC, has shown that sustainable material choices and new approaches in the quay construction phase can make a substantial difference – without driving up costs.

So far, emissions have been cut by 30% compared to traditional construction methods. The additional cost of climate measures accounts for just 1% of the total project budget – tangible evidence that sustainable construction can be both effective and cost-efficient.

“Measured against the benefits, the costs are small compared with the significant climate gains we achieve. Together with NCC, we have scrutinized every detail of construction, procurement, and methodology. By carrying out climate calculations that highlight the impact of different choices, daring to challenge conventional methods, thinking creatively, and consistently focusing on cutting emissions, we refined our initial targets and have now achieved a 30% reduction. Along the way, we’ve also gained a deeper understanding of how construction affects our CO₂ footprint, knowledge that will allow us to set even tougher requirements in future projects,” says Jan Andersson, Project Manager for Skandia Gateway at The Port of Gothenburg.

A collaborative achievement

The ability to cut emissions during quay construction rests on strong teamwork between project management and those carrying out the work on site.

“It is a great achievement to have reduced CO₂ emissions in this project so successfully. But no matter how much we plan and calculate, nothing would be possible without the skill and dedication of the people placing piles, concrete, and sheet piling on site,” says Jan Andersson.

How the emissions were reduced

Materials & construction

Material choices with lower climate impact, recycled steel instead of new, saved 15% of the entire project’s climate impact

Optimization and minimization of constructions, for example reduction of concrete thickness

Smaller proportion of cement – concrete with slag as a binder

Optimized use of concrete – the steel pipe piles are partially filled with crushed material

Thinner layers of coarse concrete

More efficient sheet piling, smaller dimensions and extent

Proposals and solutions from both officials and skilled workers on site

Machinery & transports

100% HVO100 in all machinery and transports

Electrically powered machines for piling and drilling

Consolidated orders and planned castings with other stakeholders provide fewer transports

Larger load capacity in excavation trucks provides fewer trips

Charging stations for electric cars on the construction site

Return loads – bringing new material back from the landfill

No unnecessary idling

Circular construction

Sorting & reuse of asphalt, steel, and rock masses between projects

Holes in the sheet piling = less future operation & maintenance

Reuse of masses & materials: steel piles, steel beams, asphalt, cutting waste

Pulled-up sheet piling reused for seals

Innovative work mothodology

Ongoing climate calculations showing decreasing emissions over time

Efficient procurement work with CO2 as a selection criterion

©SKANDIA GATEWAY 2020

The Port of Gothenburg is the only port in Sweden that can receive the world’s largest vessels. At present they are unable to do so fully loaded. To address this problem and ensure Swedish industry is able to meet the demands of the future, extensive deepening of the fairway is required. The project, known as Skandia Gateway, is being run jointly by the Swedish Maritime Administration and the Port of Gothenburg.